PRODUCT CENTER

Channel steel is a long strip of steel with a groove-shaped section, which is a carbon structural steel for construction and machinery. It is a section steel with a complex section, and its section shape is groove-shaped. Channel steel is mainly used for building structure, curtain wall engineering, mechanical equipment and vehicle manufacturing.

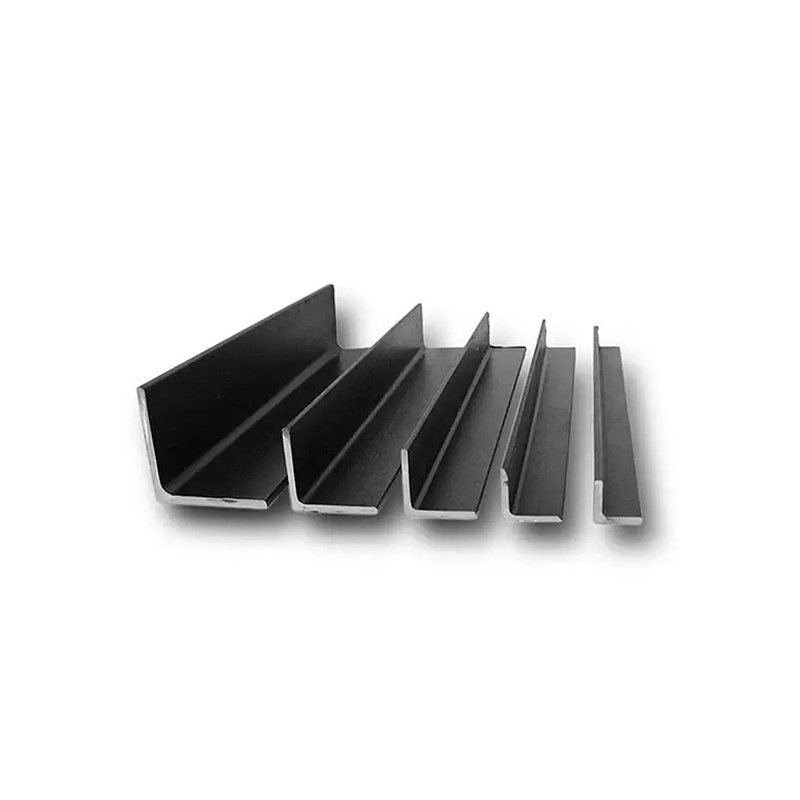

Angle steel, commonly known as angle iron, is a long strip of steel with two sides perpendicular to each other. Angle steel can be composed of different force components according to the different needs of the structure, and can also be used as a connector between components. Widely used in various building structures and engineering structures, such as beams, bridges, transmission towers, lifting and transportation machinery, ships, industrial furnaces, reaction towers, container racks, cable trench supports, power piping, bus support installation, and warehouse shelves. Angle steel is carbon structural steel for construction, is a simple section of steel, mainly used for metal components and the framework of the plant. In use, it is required to have good weldability, plastic deformation performance and mechanical strength.

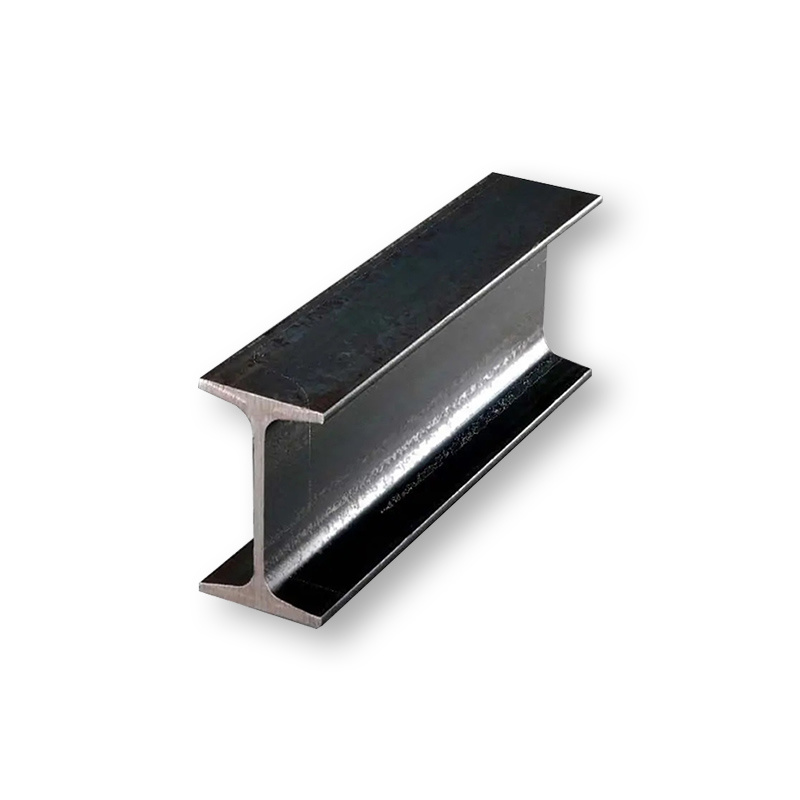

H-beam is a new type of steel for economic construction. H-beam has economical and reasonable cross-sectional shape, good mechanical properties, uniform extension of each point on the cross-section and small internal stress during rolling. Compared with ordinary I-beam, H-beam has the advantages of large cross-sectional modulus, light weight and metal saving, which can reduce the building structure by 30-40%. In addition, because its legs are parallel to the inner and outer sides and the leg ends are right angles, the welding and riveting work can be saved by 25%. It is often used in large buildings (such as factories, high-rise buildings, etc.) with large bearing capacity and good cross-sectional stability, as well as bridges, ships, lifting and transportation machinery, equipment foundations, supports, foundation piles, etc.

I-beam is mainly divided into ordinary I-beam, light I-beam and low alloy light I-beam. Ordinary I-beam and light I-beam flanges are thick on the web plate and thin on the outside. Ordinary I-beam, light I-beam, because the cross-sectional dimensions are relatively high, narrow, so the section of the two main sleeve moment of inertia difference is large, which makes it in the scope of application has a great limitation. The use of I-beam shall be selected according to the requirements of the design drawings.

The specifications and models of U-shaped steel sheet piles are rich, and the length can be specially customized according to the requirements of customers, which brings great convenience to the construction and reduces the cost at the same time.

Z-shaped sheet piles are called Zs because the single piles are shaped roughly like a horizontally stretched Z. The interlocks are located as far away from the neutral axis as possible to ensure good shear transmission and increase the strength-to-weight ratio. Z piles are the most common type of sheet pile in North America and can be used in a wide variety of applications.

CHS Circular Steel Hollow Section

As with square HSS, round steel HSS is ideal for creating uniform geometries. Round tubing is well-suited to constructing columns and features a high resistance to torsion.

Rectangular HSS is often used within welded steel frames where loading occurs from multiple directions. The flat shape makes rectangular HSS ideal for construction. It is often used to create a pleasing aesthetic effect.

Square HSS tube are available to meet ASTM A500 or ASTM A1085 specifications. Square jumbo tubing is ideal for applications requiring uniform geometry along two or more cross-sections.