PRODUCT CENTER

Galvanized angle steel is divided into hot-dip galvanized angle steel and cold galvanized angle steel. Hot dip galvanized angle steel is also called hot dip galvanized angle steel or hot dip galvanized angle steel. The cold galvanized coating mainly ensures the full contact between zinc powder and steel through electrochemical principle, and generates electrode potential difference for anti-corrosion. Hot dip galvanized angle steel is also called hot dip galvanized angle steel or hot dip galvanized angle steel. It is to immerse the angle steel after derusting in molten zinc melted at about 500 ℃ to attach a zinc layer to the surface of the angle steel, thus achieving the purpose of anti-corrosion. It is suitable for strong corrosive environments such as various strong acids and alkali fogs. The cold galvanizing process is used to protect the metal from corrosion. For this purpose, a coating of zinc filler is used. It is applied to the protected surface by any coating method and dried to form a zinc filler coating with a content of zinc in the dried coating (up to 95%). Suitable for repair work (I. e., during repair work, only where the protected steel surface is damaged, the surface can be recoated as long as it is repaired). The cold galvanizing process is used for corrosion protection of various steel products and structures.

Galvanized H-beam is a cross-sectional area distribution is more optimized, more reasonable than the economic section of high-efficiency profiles, because of its section and the English letter "H" the same name. Since all parts of the H-beam are arranged at right angles, the H-beam has the advantages of strong bending resistance, simple construction, cost saving and light structure in all directions, and has been widely used.

Hot-dip galvanized I-steel is also called hot-dip galvanized I-steel or hot-dip galvanized I-steel. It is to immerse the I-beam after derusting into molten zinc at about 500 ℃ to attach a zinc layer to the surface of the I-beam, thus achieving the purpose of anti-corrosion. It is suitable for strong corrosive environments such as various strong acids and alkali fogs.

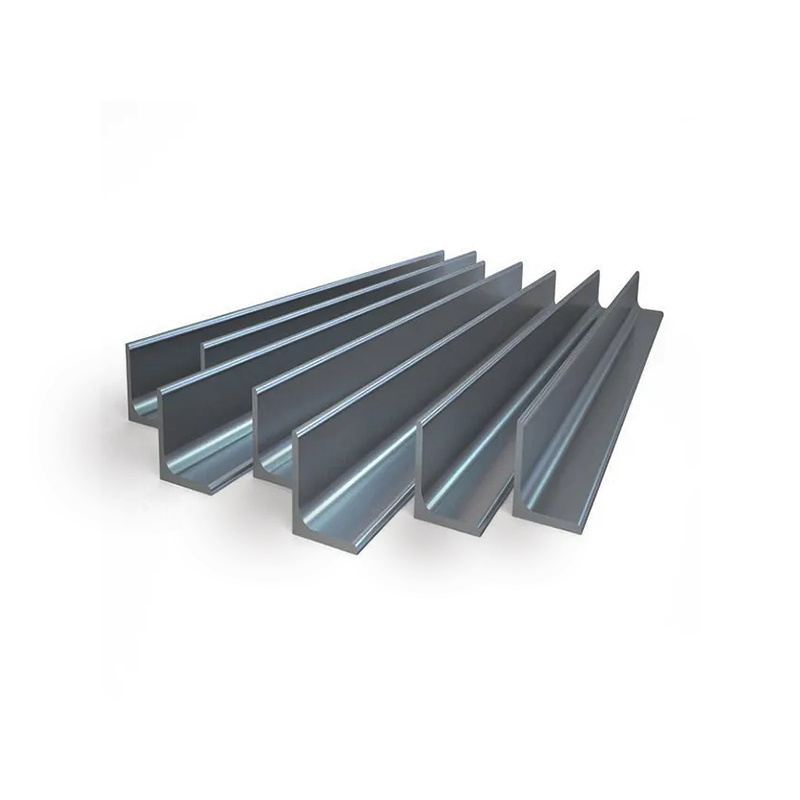

Carbon Steel Unequal Angle Steel

Unequal angle steel is widely used in various metal structures, bridges, machinery manufacturing and shipbuilding, various building structures and engineering structures, such as beams, bridges, transmission towers, lifting and transportation machinery, ships, industrial furnaces, reaction towers, container racks and warehouses.

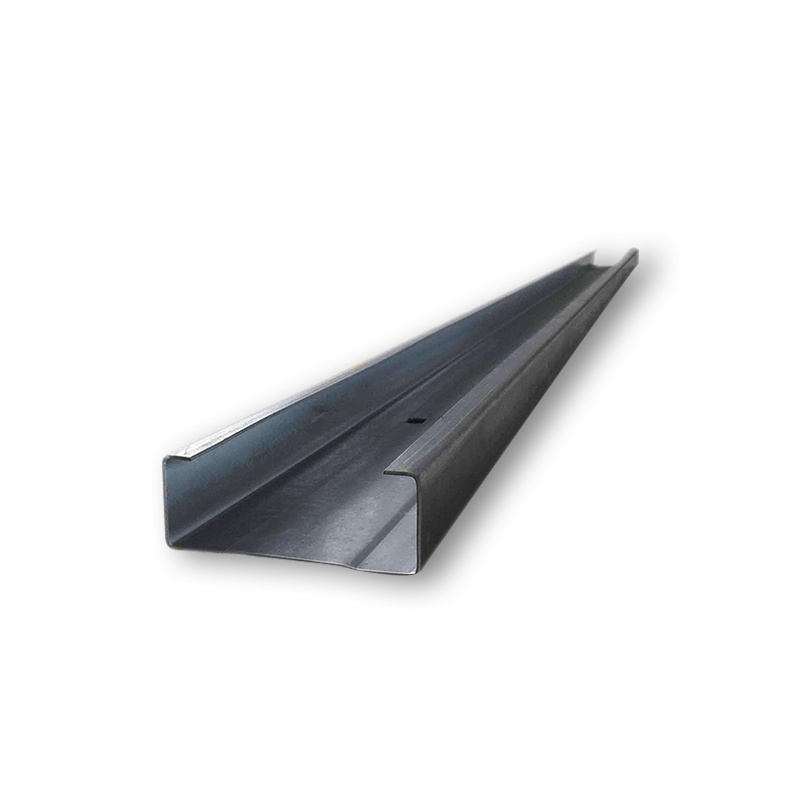

Channel steel is a long strip of steel with a groove-shaped section, which is a carbon structural steel for construction and machinery. It is a section steel with a complex section, and its section shape is groove-shaped. Channel steel is mainly used for building structure, curtain wall engineering, mechanical equipment and vehicle manufacturing.